Multi-injector

-

Operating width

6,3 m Working fluid consumption70–700 l/ha -

Field speed

5–15 km/h

-

Working fluid consumption

70–700 l/ha Field speed5–15 km/h -

Operating width

6,3 m

About multi-injector

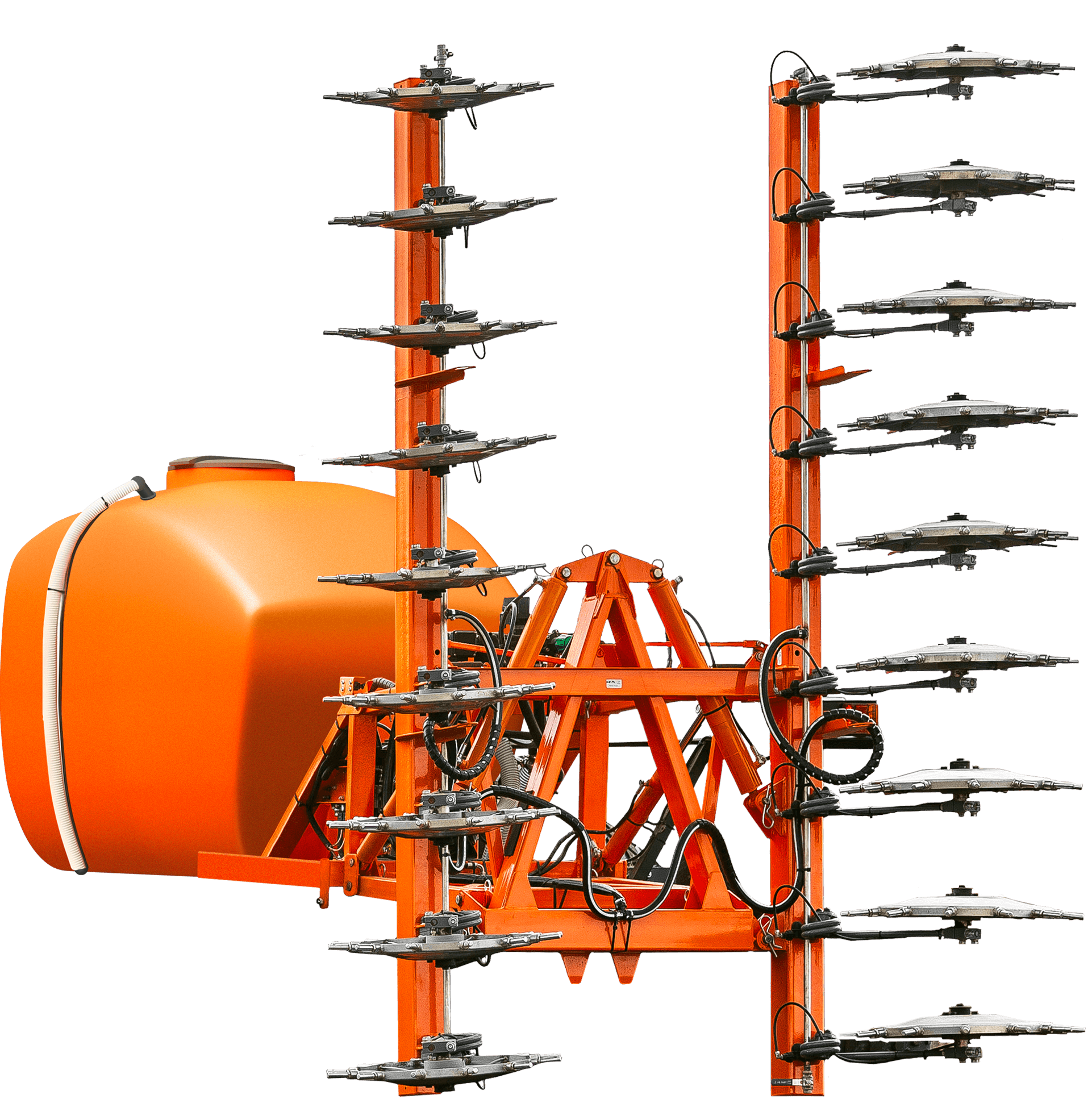

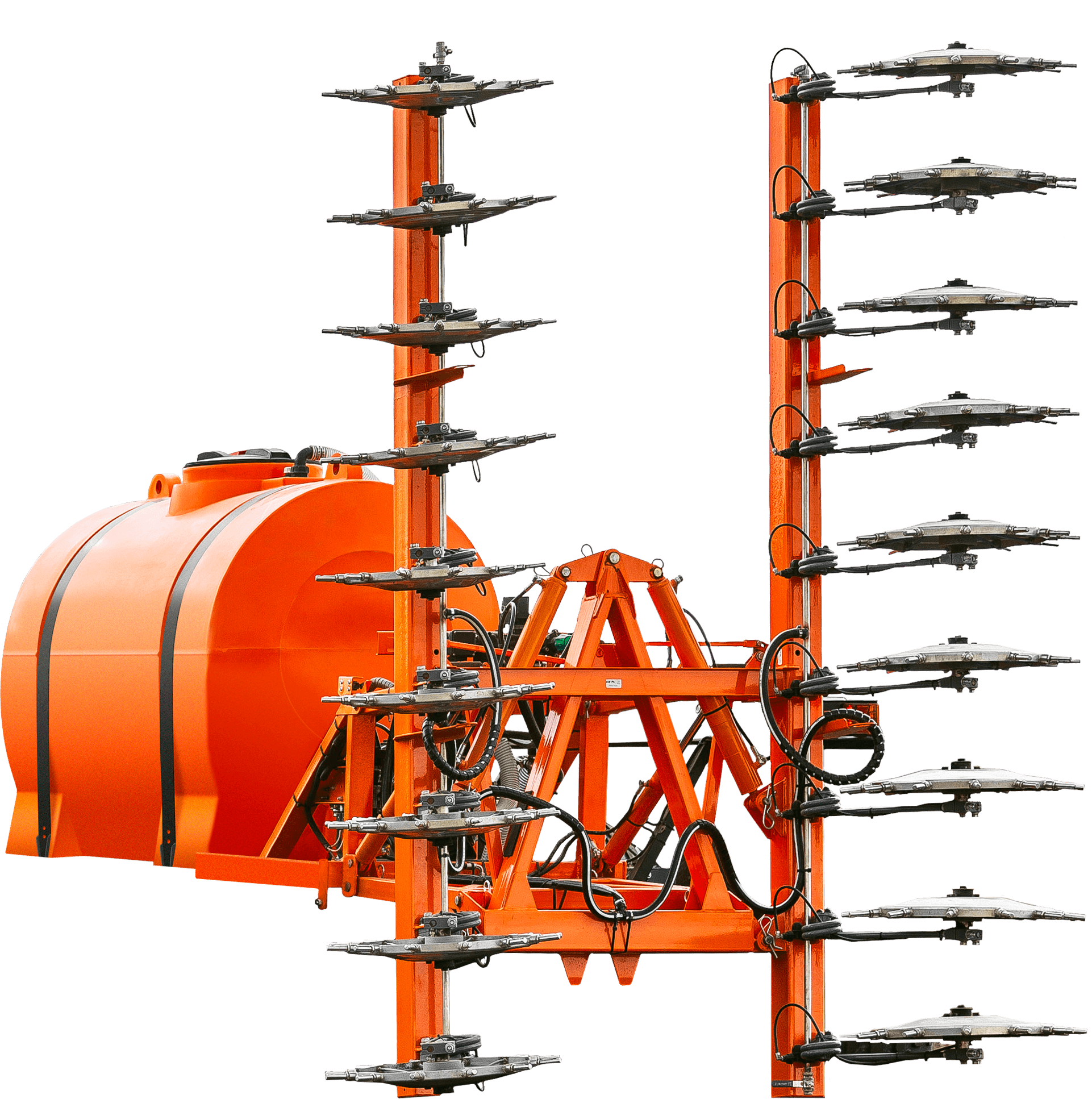

A multi-injector is designed for spot injecting of liquid fertilizers. The module is equipped with two consoled injection wheels. The liquid is injected into the soil to the desired depth by means of the long needles on the wheels. The device is ideal for mulching and direct seeding fertilization as the nutrients are delivered directly to the roots.

Comparison of the "Tuman" line multi‑injectors

Right into

the soil

Tuman-3

|

Tuman-2M

|

|

|---|---|---|

| Operating width |

|

|

| Injection wheels |

|

|

| Row spacing |

|

|

| Tank volume |

|

|

| Working fluid consumption |

|

|

| Field speed |

|

|

Equipment

Consoles, suspension blocks, injection wheels

Suspension blocks for injection wheels are installed on the console.

Each suspension block is equipped with a spring intended for immersing the needles of the wheels into the soil.

| Number of injection wheels | 18 pieces | 18 pieces |

| Distance between wheels | adjustable | adjustable |

| Number of needles on the wheel | 12 pieces | 12 pieces |

| Distance between injection points on the wheel | 170 mm | 170 mm |

| Tank capacity | 2000 l | 2500 l |

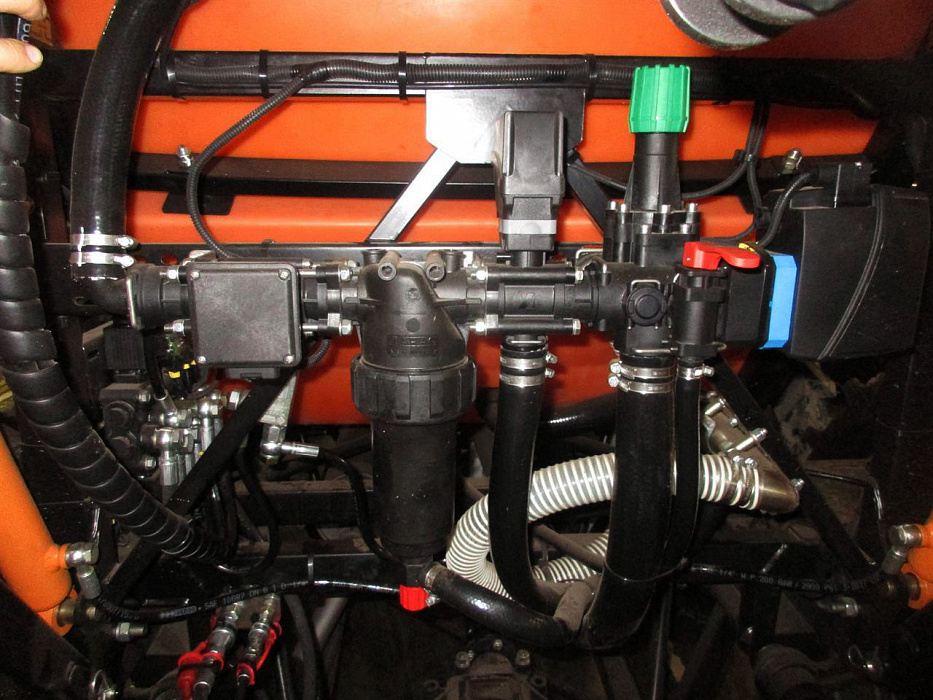

Flow rate and reservoir

Fertilizer tank is equipped with a hydro-mixer maintaining a uniform concentration of substances throughout the volume.

Water is pumped into the tank through the filling connection using an external filling pump. The drug is added manually through the top of the tank.

The pump provides pressure in the system and a uniform supply of the mixture to the distribution fittings on the suspension. The valve doses the mixture and delivers it to the nozzles located on the consoles. The solution is supplied from the nozzles to the injection wheels.

To the last

drop

| Tuman-2M | Tuman-3 | |

|---|---|---|

| Tank capacity | 2000 l | 2500 l |

| Working fluid consumption |

|

|

| Fuel consumption |

|

|

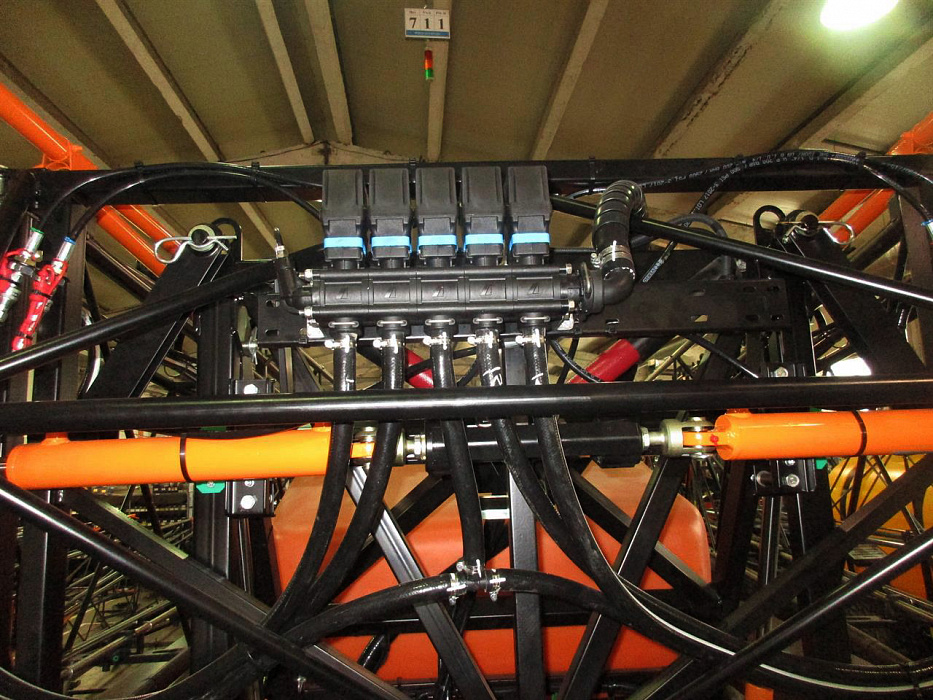

Computers and chemical systems equipment

The flow controller is installed in the cabin. All operating parameters are set by a computer. The interface is key operated.

The efficiency

in 2 times higher

Bars-5

Application variations

Complex solutions

Atlas + Bars-5

Manual control of sections

Automatic flow control mode

Manual flow control mode

Driving in parallel lines

Capability to work at night

Overlap visualization

Creating of field boundaries

Calculation of area

Automatic sections control