Fertilizer spreader

-

Efficiency

up to 50 ha/h Operating widthup to 28 m -

Fuel consumption

0,25–0,35 l/ha

-

Efficiency

up to 50 ha/h Operating width28 m -

Fuel consumption

0,2–0,25 l/ha

-

Efficiency

up to 60 ha/h Operating widthup to 28 m -

Fuel consumption

up to 0,25 l/ha

About fertilizer spreader

The spreader is designed for surface application of dry granular mineral fertilizers starting from early spring (on a snow shard) and during the optimum terms.

Comparison of the "Tuman" line spreaders

For a wide

range of tasks

Tuman-3

|

Tuman-2M

|

Tuman-1M

|

|

|---|---|---|---|

| Field speed |

|

|

|

| Efficiency |

|

|

|

| Hopper volume |

|

|

|

| Operating width |

|

|

|

| Fertilizer application rate |

|

|

|

| Soil pressing |

|

|

|

| Fuel consumption |

|

|

|

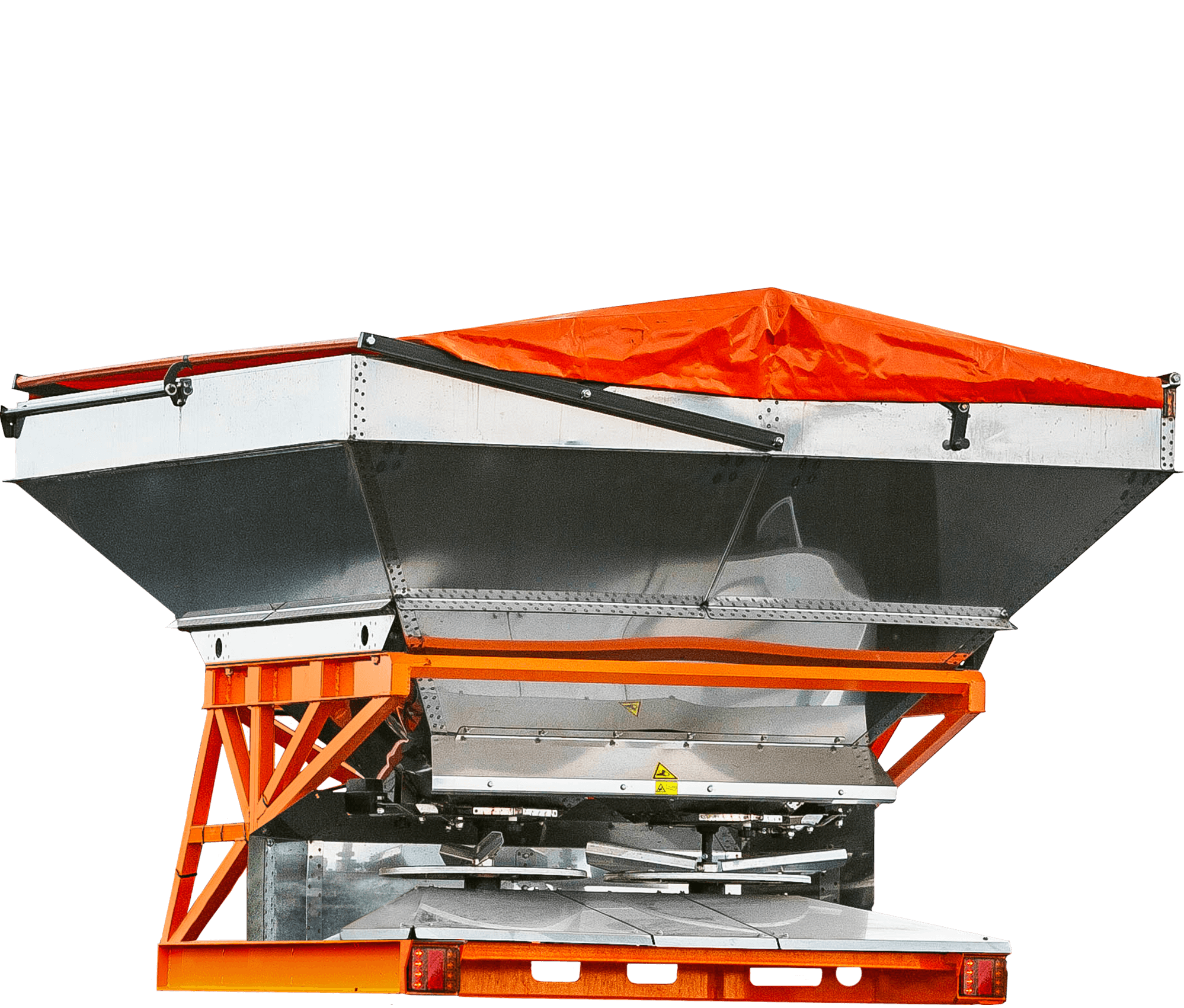

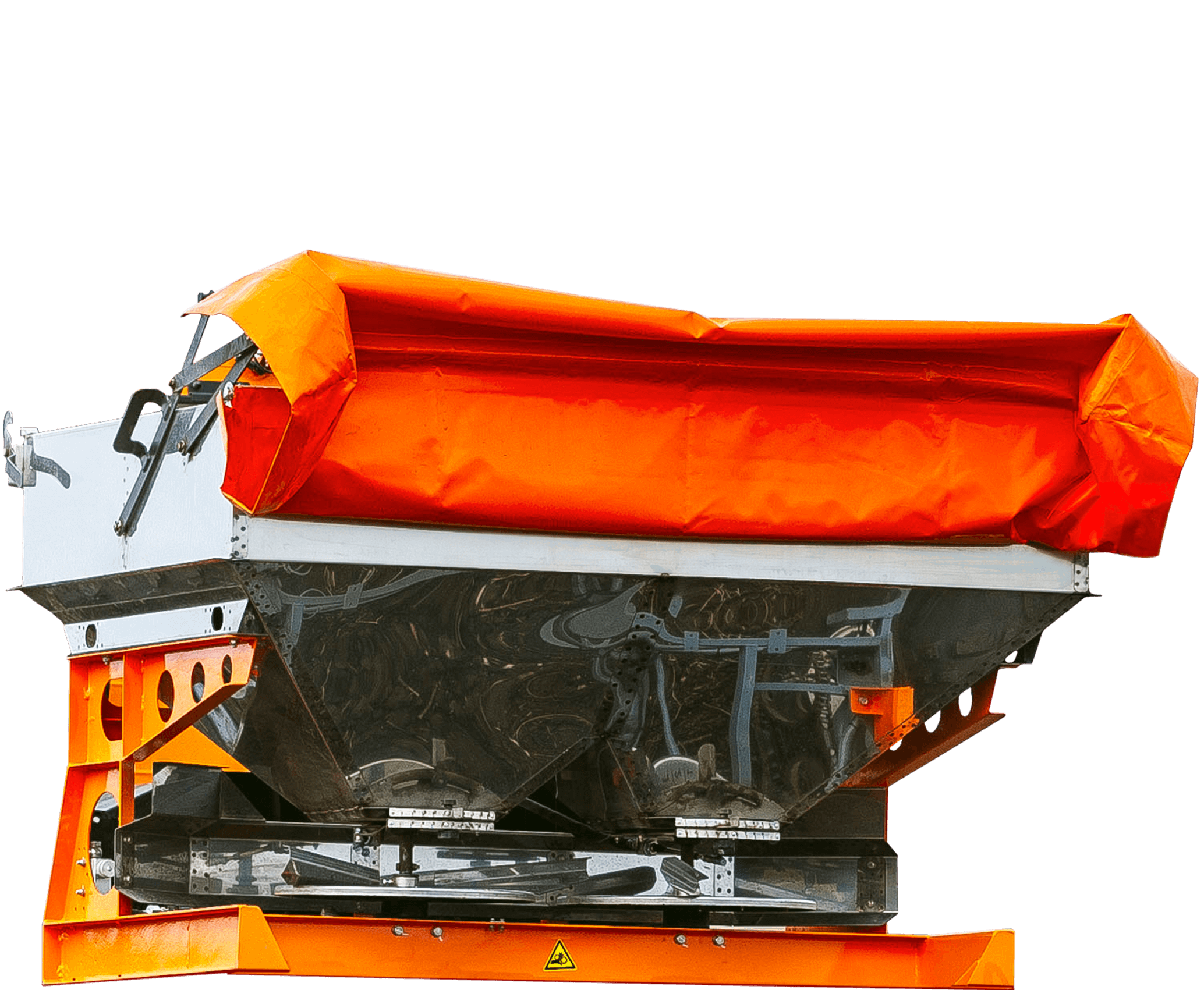

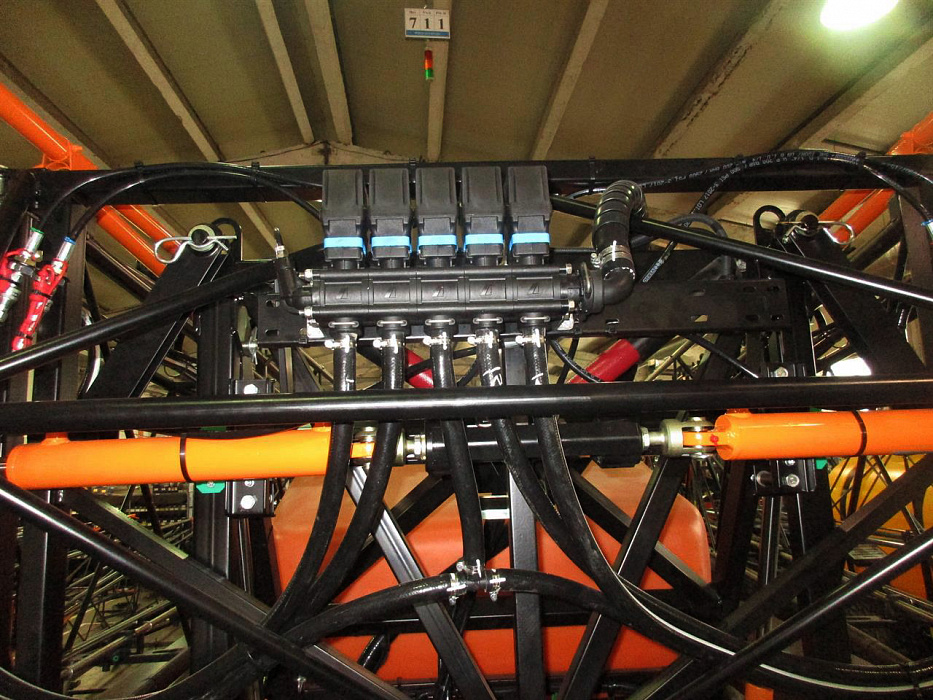

Equipment

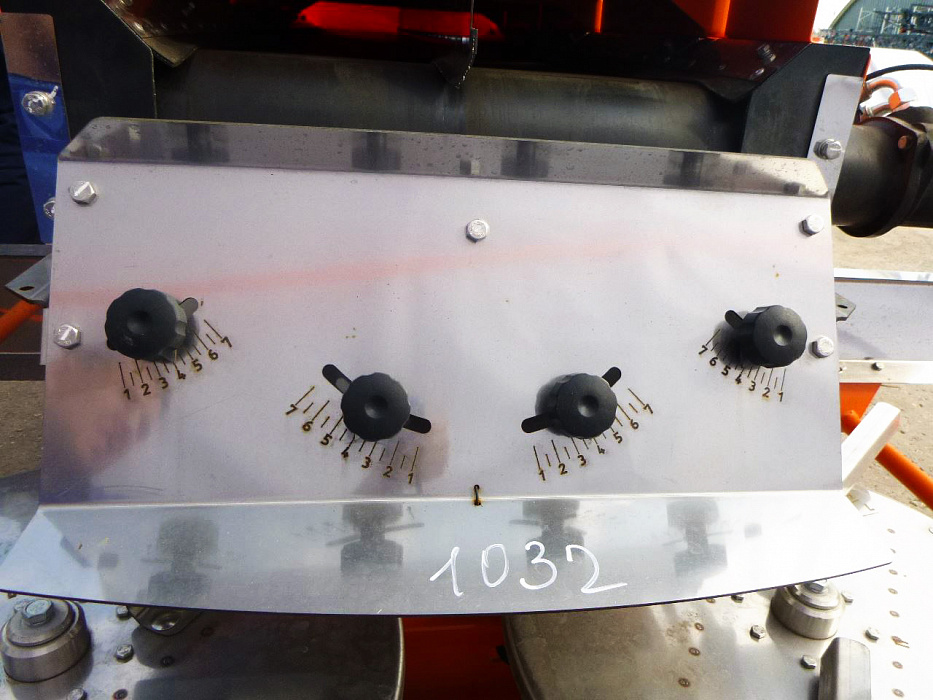

Spreading discs, chokes

The spreading discs are made of stainless steel. The rotational speed of the discs is 750 rpm.

Fertilizer consumption can be adjusted by setting the extreme position of the metering choke. The choke is equipped with an electric actuator that gradually opens or closes it depending on the speed of movement.

The setting choke is used to regulate the delivery point to the discs, which determines the distribution pattern of the fertilizer across the working width.

A universal

solution

| Tuman-1M | Tuman-2M | Tuman-3 | |

|---|---|---|---|

| Operating width |

|

|

|

| Number of spreading discs | 2 pieces | 2 pieces | 2 pieces |

| Rotation speed of spreading discs | 750 ±50 rpm | 750 ±30 rpm | 750 ±30 rpm |

Flow rate and reservoir

The hopper for dry granular mineral fertilizers made of stainless steel is equipped with a special mesh that prevents large clods of fertilizers and debris from getting onto the spreading discs.

To the very last

granule

| Tuman-1M | Tuman-2M | Tuman-3 | |

|---|---|---|---|

| Hopper volume | 1000 l | 2000 l | 2500 l |

| Fertilizer consumption |

|

|

|

| Fuel consumption |

|

|

|

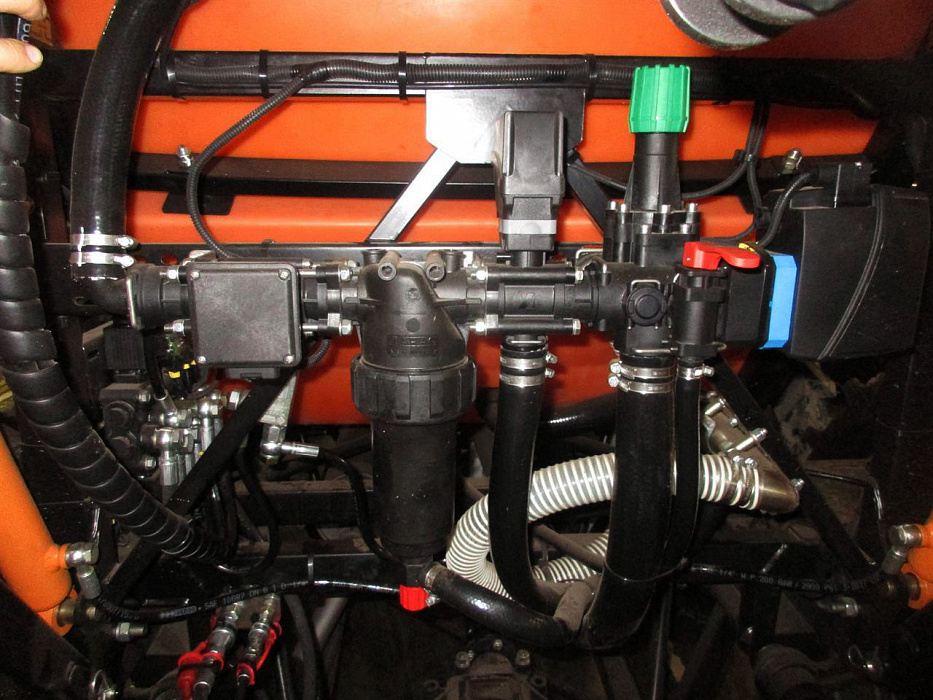

Computers and chemical systems equipment

The flow controller is installed in the cabin. Operating width, application rate, fertilizer density, speed and hopper correction factors are set by a computer. The interface is key operated.

The spreader flow controller is used to adjust the application rate.

The efficiency

in 2 times higher

Bars-5

Application variations

Complex solutions

Atlas + Bars-5

Manual control of sections

Automatic flow control mode

Manual flow control mode

Driving in parallel lines

Capability to work at night

Overlap visualization

Creating of field boundaries

Calculation of area

Automatic sections control