Boom sprayer

-

Efficiency

up to 80 ha/h Operating width28 m -

Working fluid consumption

15–450 l/ha

-

Efficiency

up to 80 ha/h Operating width28 m -

Working fluid consumption

30–300 l/ha

-

Efficiency

up to 60 ha/h Operating width20 m -

Working fluid consumption

10–180 l/ha

About boom sprayer

A boom sprayer applies liquid fertilizers and irrigates field crops with pesticides, including those cultivated using intensive technology. The sprayer allows spraying substances most accurately, evenly and quickly.

Comparison of the line "Tuman" boom sprayers

For a wide

range of tasks

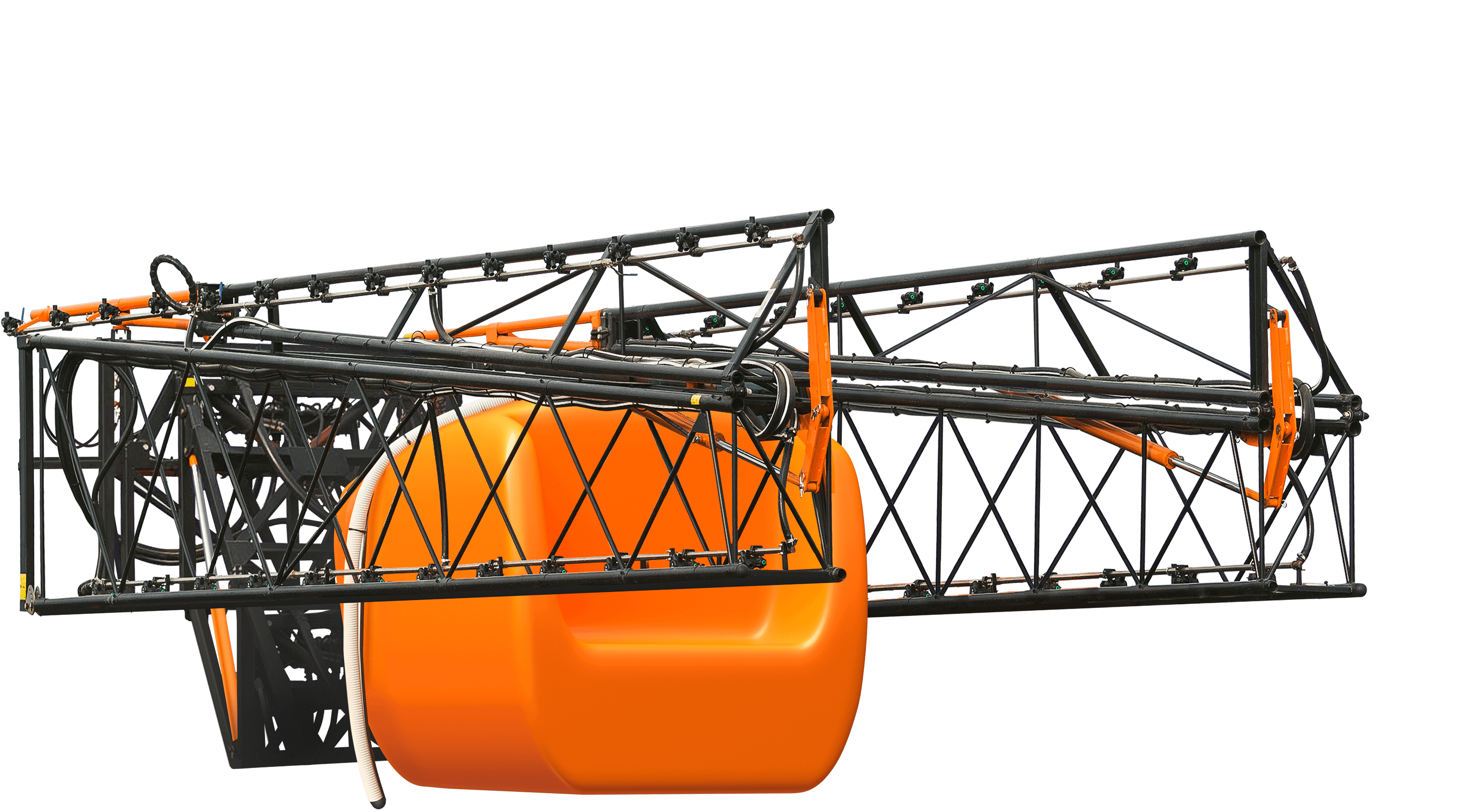

Tuman-3

|

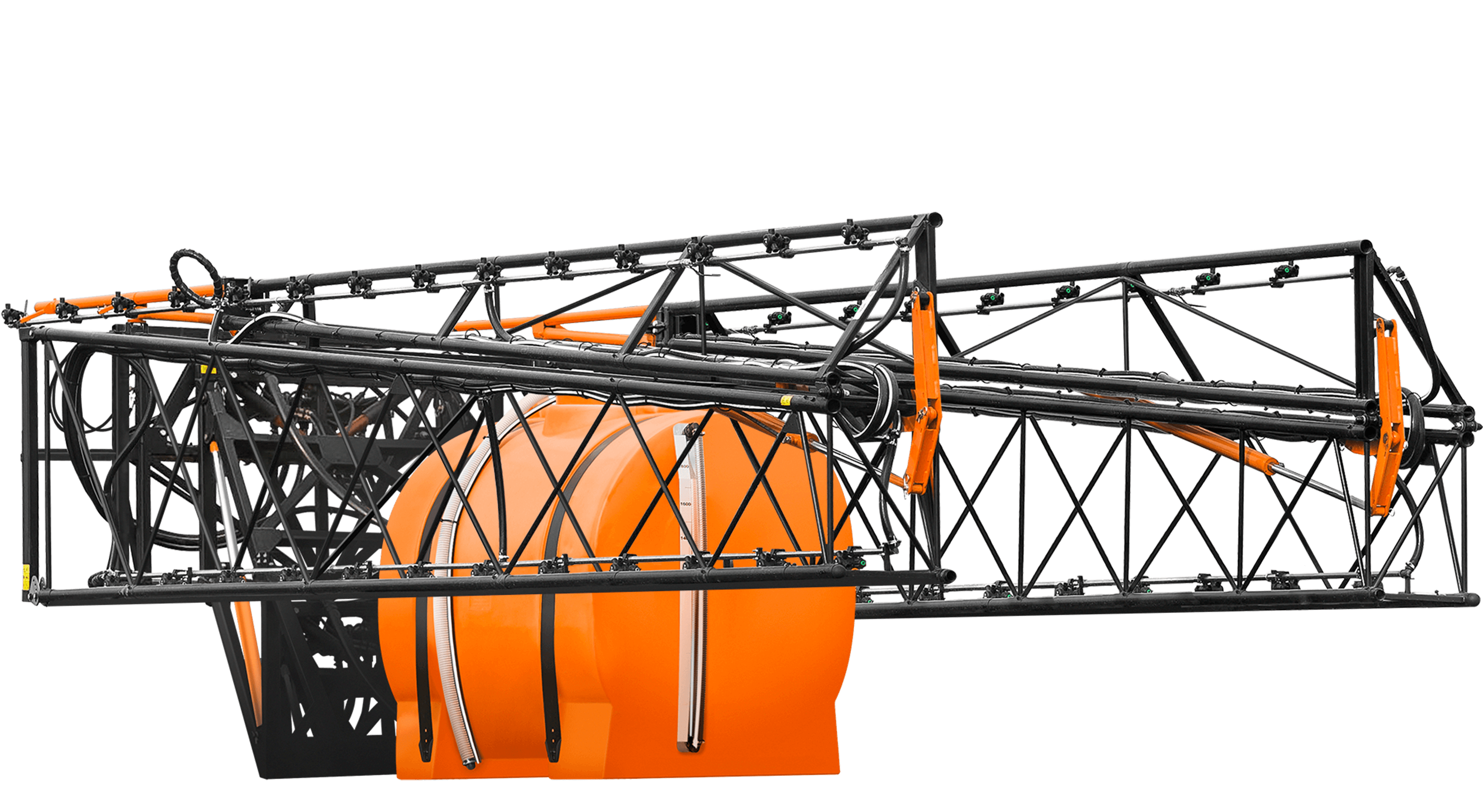

Tuman-2M

|

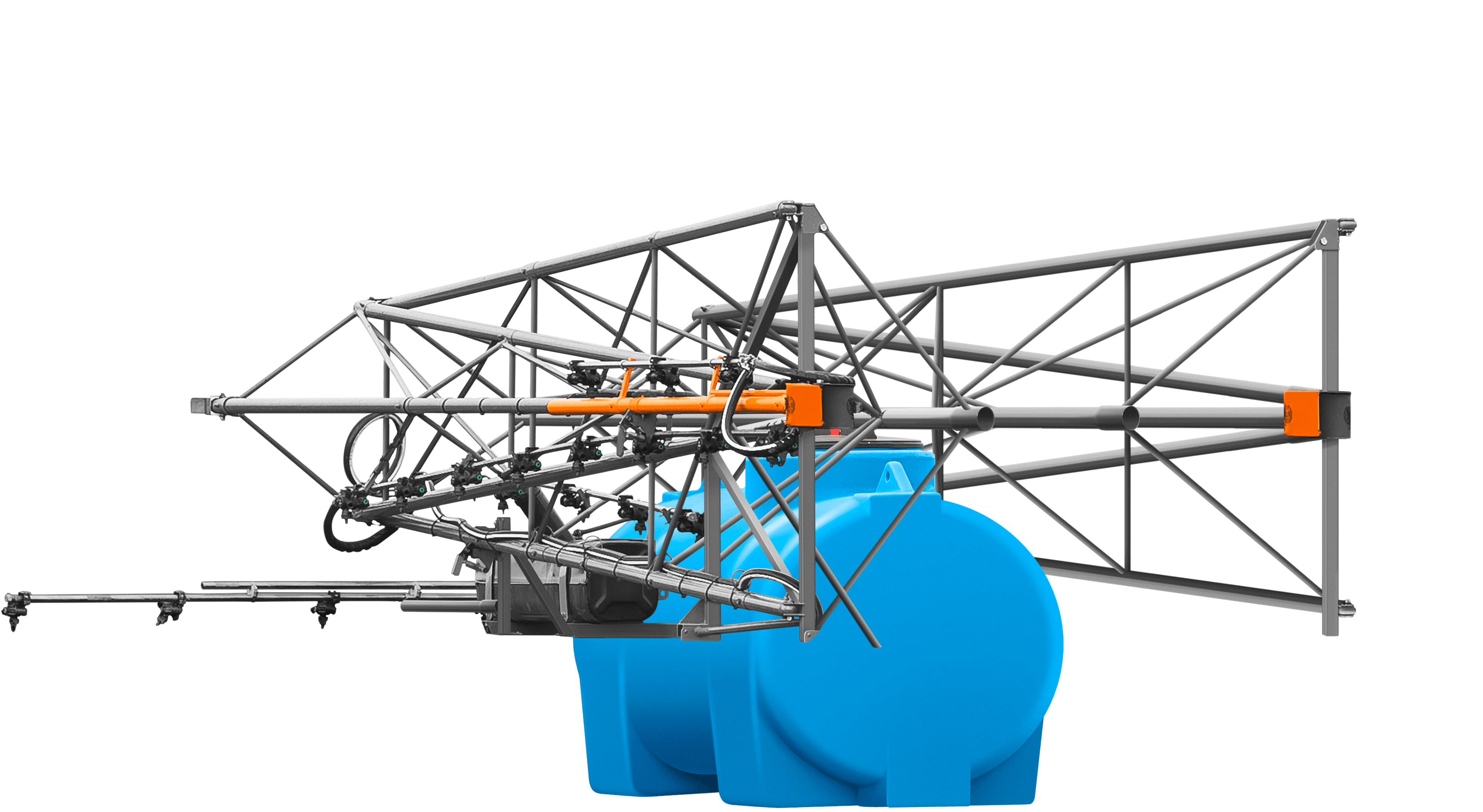

Tuman-1M

|

|

|---|---|---|---|

| Field speed |

|

|

|

| Efficiency |

|

|

|

| Tank volume |

|

|

|

| Operating width |

|

|

|

| Working fluid consumption |

|

|

|

| Soil pressing |

|

|

|

| Fuel consumption |

|

|

|

| Clearance |

|

|

|

| Track |

|

|

— |

Equipment

Booms and sprayers

The sprayer is equipped with ultra-light D16 alloy booms on a pendulum suspension. The booms are equipped with stainless steel manifolds capable of accommodating up to 5 nozzles. Depending on the task, the nozzles can be quickly replaced by the torch suitable in size and configuration.

A universal

solution

|

|

Tuman-1M |

Tuman-2M |

Tuman-3 |

|---|---|---|---|

|

Operating width |

20 m |

28 m |

28 m |

|

Number of nozzles |

40 pieces |

48 pieces |

48 pieces |

|

With tips |

— |

56 pieces |

56 pieces |

Flow rate and reservoir

A tank is equipped with a hydro-mixer maintaining a uniform concentration of substances throughout the volume.

A filling mixer ensures safe and efficient filling of substances into the tank.

A fuel can washer allows draining the tank substances.

To the last

drop

|

|

Tuman-1M |

Tuman-2M |

Tuman-3 |

|---|---|---|---|

|

Tank capacity |

1000 l |

2000 l |

2500 l |

|

Working fluid consumption |

|

|

|

|

Working pressure inside the delivery line |

0,15–0,6 MPa |

0,15–0,8 MPa |

0,15–0,6 MPa |

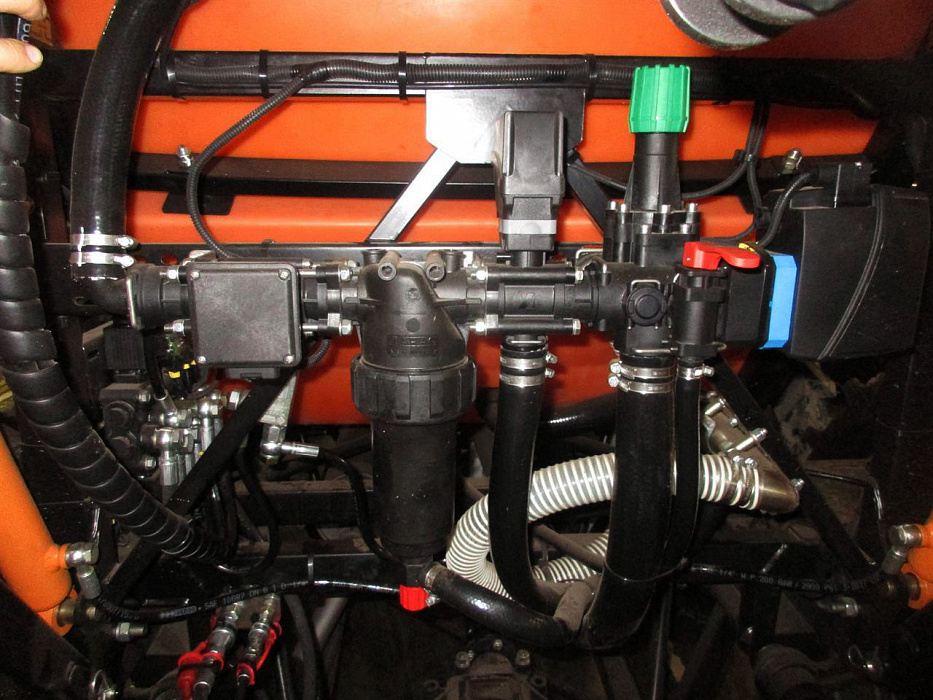

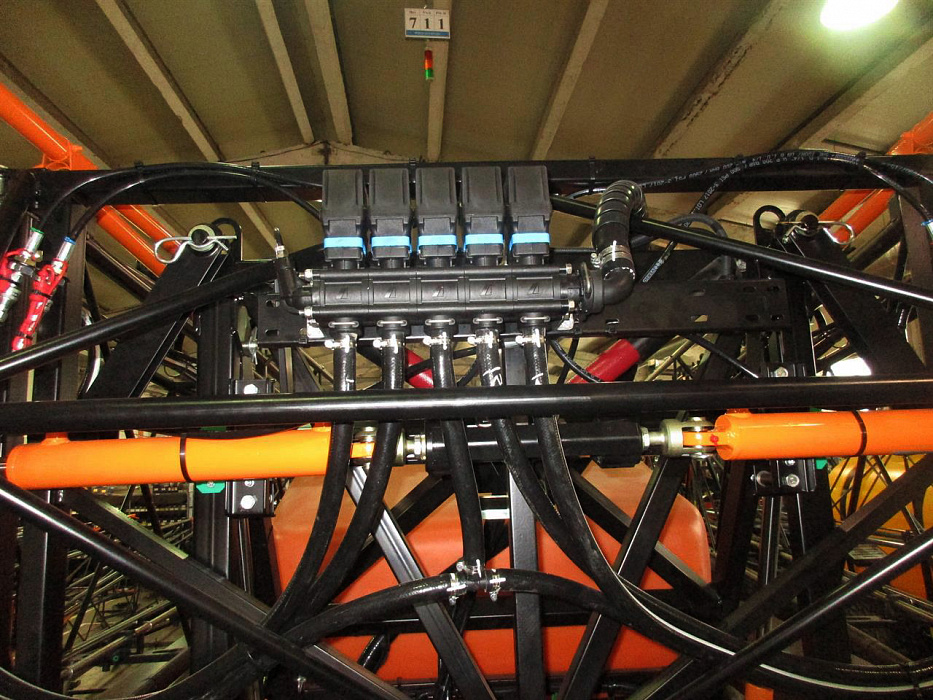

Computers and chemical systems equipment

Computers regulate the fluid flow and control various operation processes. Depending on the configuration, various computer options are possible.

The chemical pump ensures a stable and uniform supply of substances from the tank to the dispenser.

The distributor is controlled by a computer and doses the mixture supplied to the sprayers.

The efficiency

in 2 times higher

Bars-5

Application variations

Complex solutions

Atlas + Bars-5

Manual control of sections

Automatic flow control mode

Manual flow control mode

Driving in parallel lines

Capability to work at night

Overlap visualization

Creating of field boundaries

Calculation of area

Automatic sections control