Fan sprayer

-

Spraying width at zero wind

50 m Working fluid consumption10–80 l/ha -

Operating pressure

up to 10 atm Fuel consumptionup to 60 l/ha

-

Spraying width at zero wind

50 m Working fluid consumptionдо 60 l/min -

Operating pressure

up to 10 atm Fuel consumptionup to 60 l/ha

About fan sprayer

The fan sprayer is designed for chemical working of fields, gardens, granaries, industrial warehouses using the aerosol method. Insecticides and fungicides suit excellently for fields borders working.

Comparison of the "Tuman" line fan sprayers

For a wide

range of tasks

Tuman-2M

|

Tuman-1M

|

|

|---|---|---|

| Spraying width at zero wind |

|

|

| Spraying width downwind |

|

|

| Tank volume |

|

|

| Field speed |

|

— |

| Nozzles |

|

— |

| Working fluid consumption |

|

|

| Turning from the cabin |

|

— |

| Number of nozzles |

|

|

| Operating pressure |

|

|

| Fuel consumption |

|

|

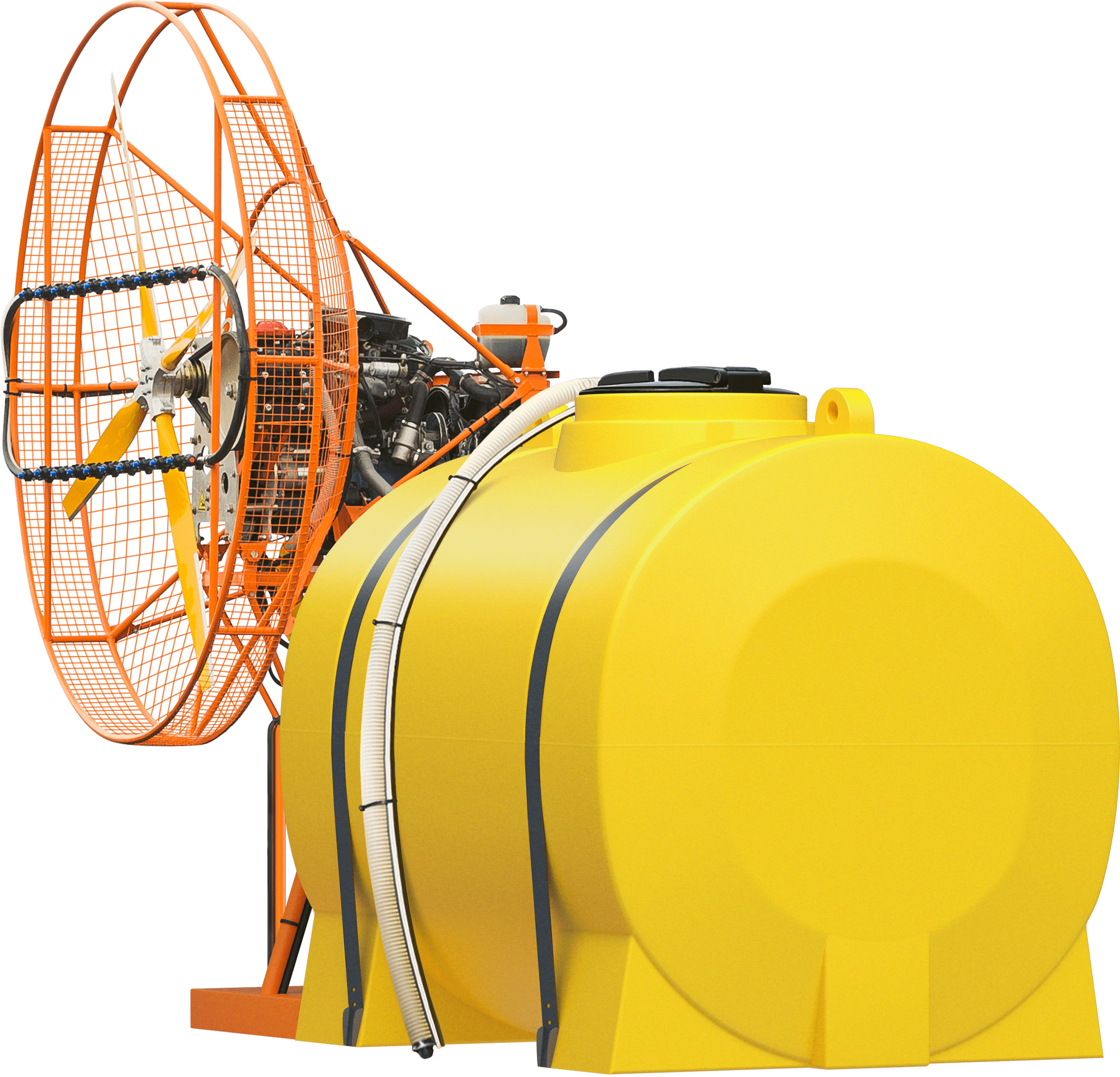

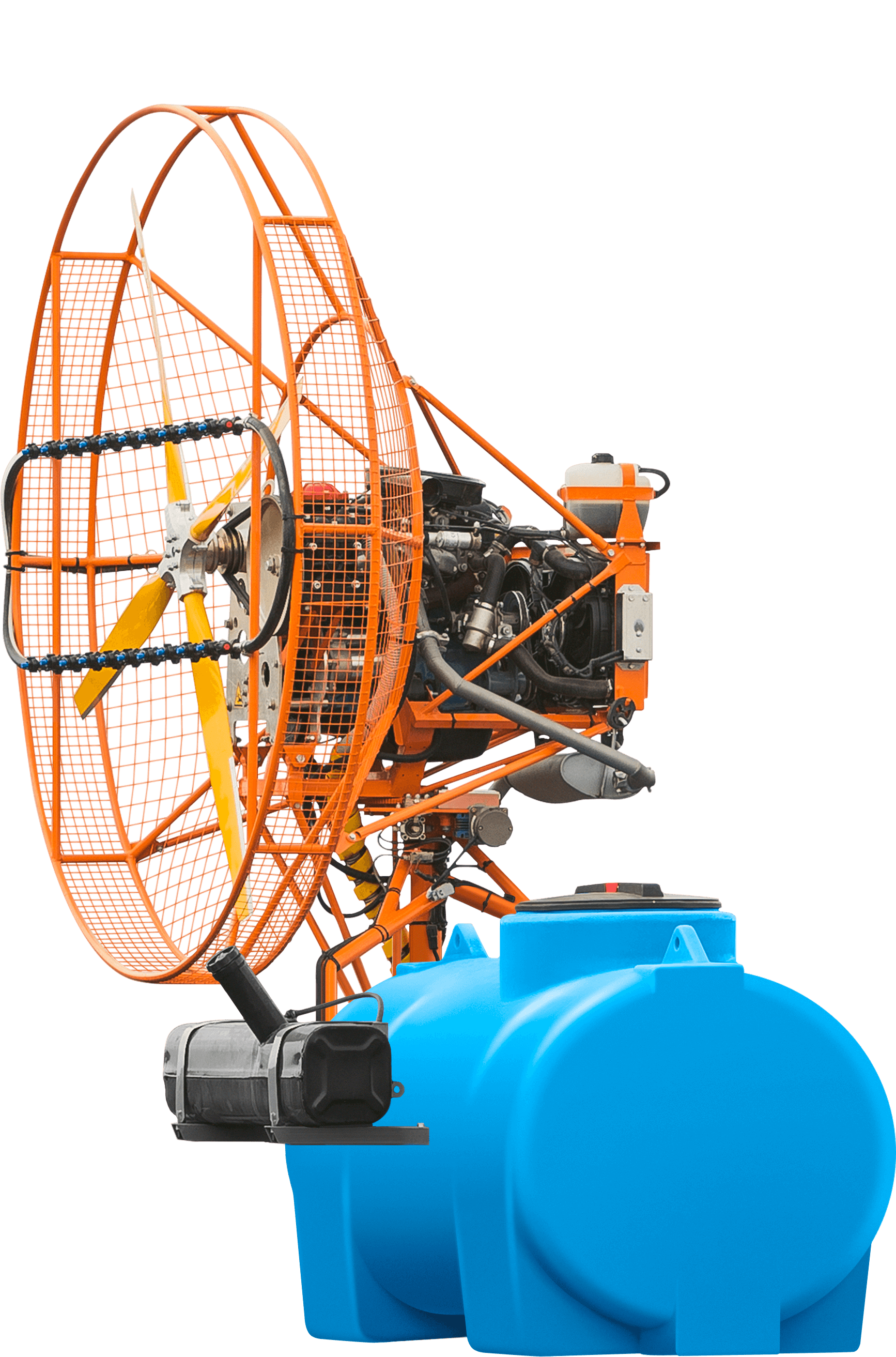

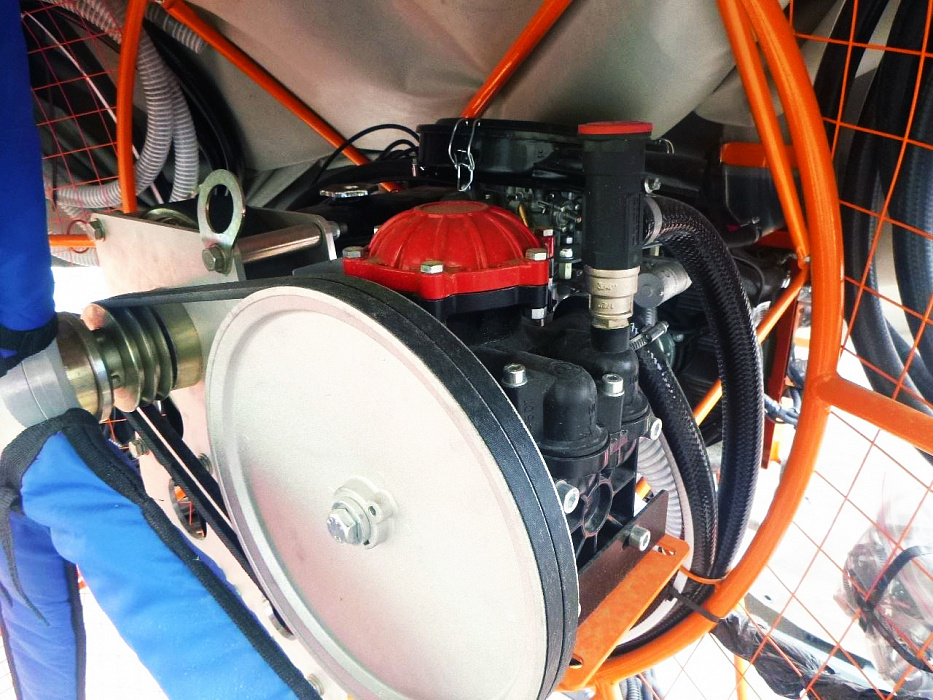

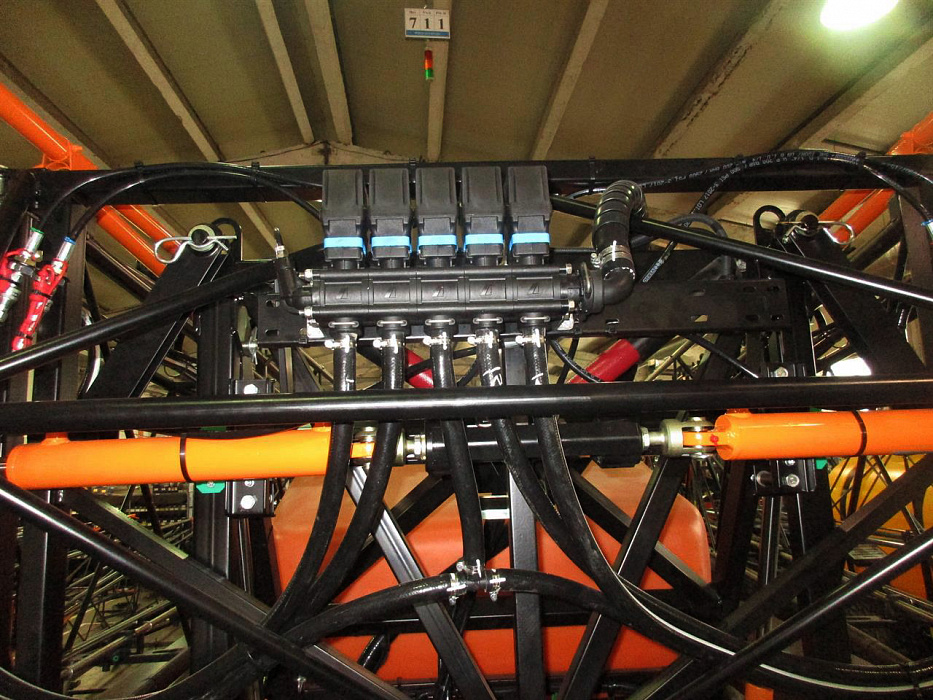

Equipment

Fan, chemical pump, propeller and nozzles

The chemical pump supplies the drugs from the tank to the nozzles on the fan constantly and evenly. The nozzles spray the mixture into the air flow created by the propeller. The aerosol flies with an air stream at a distance of up to 150 m. The fan is capable to rotate in any direction within 90 degrees.

A universal

solution

| Tuman-1M | Tuman-2M | |

|---|---|---|

| Fan diameter | 1,85 m | 1,85 m |

| Number of blades | 4 pieces | 4 pieces |

| Swept area | 2,69 m2 | 2,69 m2 |

| Number of nozzles | 20 pieces | 20 pieces |

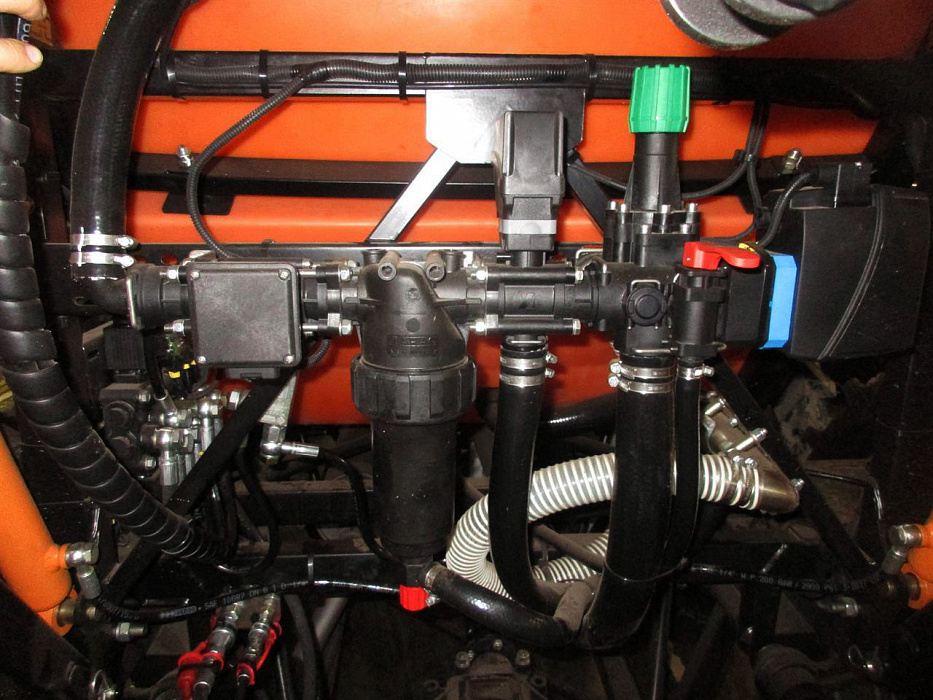

Flow rate and reservoir

The tank is equipped with a hydro-mixer, which maintains a uniform concentration of substances throughout the whole volume.

The mixture passes through a coarse purification filter and enters a pump of the chemical system. The pump delivers the drug to the fittings and further to the manifolds with nozzles.

To the last

drop

| Tuman-1M | Tuman-2M | |

|---|---|---|

| Spraying width at zero wind | 50 m | 50 m |

| Tank capacity | 1000 l | 2000 l |

| Operating pressure | 1 MPa | 1 MPa |

| Consumption | up to 80 l/ha | up to 80 l/ha |

Computers and chemical systems equipment

The flow controller is installed in the cabin. Operation parameters such as an operating width, an application rate, a fertilizer density, speed and hopper correction factors are set by means of a computer. The interface is key operated.

The efficiency

in 2 times higher

Bars-5

Application variations

Complex solutions

Atlas + Bars-5

Manual control of sections

Automatic flow control mode

Manual flow control mode

Driving in parallel lines

Capability to work at night

Overlap visualization

Creating of field boundaries

Calculation of area

Automatic sections control